Develop selective and individualized ACF treatment aiming at different VOCs waste gases;

The adsorption efficiency can reach more than 99%;

adsorption capacity is 2 times of the conventional adsorption material under same condition, and the covering area of equipment is half and operation energy utilization with low installed power;

Realize the cyclic utilization of solvent material;

VOCs can be discharged up to the standard after adsorption and purification;

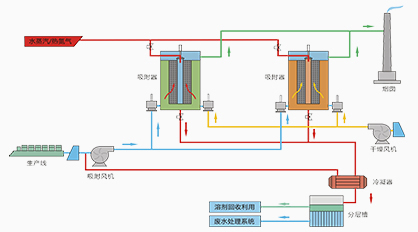

Adsorption recovery is a method taking advantage of the adsorption material to adsorb the organic solvent in waste gas and then desorb it for recovery. Through adsorption recovery system, it can not only decrease the VOCs concentration in waste gas to reach emission standard, but also put the collection into producing after desorption to realize the cyclic utilization and reduce the materials consumption.

When the waste gases which contain VOCs pass through adsorbent material bed, the VOCs is adsorbed into the micropores of adsorbent material, then the cleaning gas is released to the air. Before the adsorption penetrated, it should go through desorption and regeneration, then is carried off by carrier. Adsorbent should be heated correspondingly when adsorbed substance is heated for vaporization. Low temperature is good for adsorption, so sweeping is essential for reducing the temperature of adsorbent material.