● Provide air which has been treated for production equipment thus becoming the important part of the whole production process;

● Extremely high application requirements - extremely dry (low dew point) and / or cold / hot air temperature;

● Provide well-designed solutions for production and application;

● Excellent process control.

● Industrial air conditioner (not production process) adjusts the air quality to make the production smooth or enhance the efficiency of personnel and /or equipments;

● Air conditioner which can control the temperature and humidity independently;

● Proper application which only for reduce the humidity

● Nearly no or small-sized engineering modification;

● Controller usually connects to the interface of the management system of buildings.

● Provide adjusted air to space/buildings;

● Control humidity or temperature

● Standard storage equipment, waterworks, factory cooling, space regulations

● Standard product application supported with fundamental control device

Dehumidification Rotor applies high-efficient activated silica gel or Zeolite, equipped with central and peripheral wheel disk made by galvanized steel, with the two ends of the central hub equipped with one pair of fully enclosed ball bearings.

Dehumidification Rotor box is welded by square steel tube and box side panel which was cut by laser. It has good structure rigidity, the dual anti-corrosion treatment process which is sprayed integrally after galvanization ensures the corrosion resistance and life length of box. Rotor box body is divided into “T” type and “Y” type according to the different position of regenerative heating zone. Customer can select in accordance with the general design requirement of dehumidification device.

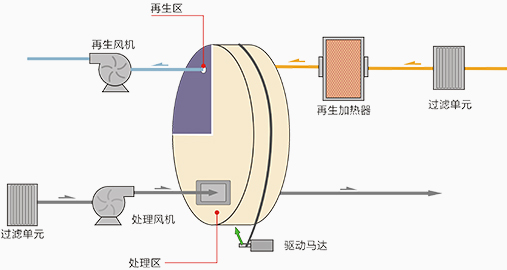

The Dehumidification Rotor inside the dehumidification part is divided by section sealing system into two zones, treatment zone and regeneration zone, and the slow rotation of rotor contributes to the complete and continuous dehumidification process. When the air treated passes through the treatment zone, the water vapor is absorbed by the dehumidification medium in the rotor, then the water vapor is phase changed and latent heat is released, and rotor gradually become dehumidification saturation. At that time, the air treated becomes dry and hot because of the moisture reduced. Meanwhile, in the regeneration zone, another route of air passes through the regeneration heater to became high temperature air (usually 100℃ to 140℃); which pass through the rotor of dehumidification saturation, and to evaporate the adsorbed water in the rotor to recover the dehumidification capability; at the same time, regeneration air became moist air because of the moisture evaporated; then the moist air is discharged to the outdoor by regeneration draught fan. It is as shown in the following figure (same as VOCs treatment):

The dehumidification technology of Napotec® rotor can provide service for a variety of technically demanding industries, including: the production, processing and cold storage of food, the pharmaceutical manufacturing, the retention of archives, paper and national defense equipment, and the anti-corrosion control of bridges; the fabrication of lithium battery, electronic product and semiconductor; skating rink and swimming pool; coating and painting industry; data center, etc.